Despite a lukewarm economy, our niche market in the firearms industry is still seeing unprecedented spikes in sales. Given my background in economics, I saw this as a classic case of supply and demand, but instead of breaking out my Excel sheet to start forecasting market impact, I thought, “How can this be an advantage to our rep agency business?”

The answer seems relatively clear — an increased demand must mean manufacturers are hungry for suppliers to ramp up production. The short answer would be “Yes,” however, our ability to get in front of these large manufacturers so we could introduce a new supplier was narrow, at best. One angle a rep would think of in terms of getting a purchasing manager’s attention would be cost or price. While trying to sell based on price can be an effective tactic, it is quite ineffective in this case. At this point in time, many manufacturers in the firearms industry are very wary of change — even if that change comes with reduced cost.

Additionally, many of these potential customers employ lean manufacturing, along with lean supply-chain management. It would be difficult to get our principals any face time with purchasing, but there had to be a way to help both the potential customer and our principal.

My father, John Aiello, owner/founder of PSE Associates, LLC, and I sat down to figure out how we could grow our business in the firearms market. Large barriers to entry meant a strategy that had worked for us in the past simply wouldn’t work this time around. The game had changed. While we had great relationships with some of the largest firearm manufacturers, we wanted to round out more of our business and cross sell our line card to more customers. How would we do it?

Implementing Risk Management

It all came down to risk management. Before joining my father’s firm in 2010, I lived in the world of risk management as an equities analyst and I understood the metrics of risk and how to parlay that into a strategy that could work for our rep business. My dad and I began gathering information about the general manufacturing industry, then we honed in on topics such as supply-chain management. It was through this initial research that we decided our new tactic would be to help customers mitigate their risk in their supply chains, and the second source campaign was born. PSE Associates has always positioned itself as a partner that works with customers to find better solutions, and risk management became a natural extension of that partnership.

Second Source Supply

Second source supply chains are ways for the manufacturer to mitigate risk and allow for supplier collaboration which can provide benefits in both price and timeliness. Simply stated, a manufacturer would identify those parts “critical” for production and bring on board two suppliers to serve the needs of that particular component part. In the event that one of the suppliers fails for whatever reason (act of God, part dysfunction, etc.), the manufacturer would be insulated from supply chain disruption as a result.

Our research led us to have a better understanding of supply-chain risk; something that we’ve heard is of great concern for many of our customers. These risks pose a major threat to the continuity of the business given that a break in the supply chain can not only reduce a company’s revenue but can also decrease market share, inflate costs and threaten production and distribution.

We decided that our angle would be to approach these large manufacturers, not in aiming to be their ONLY supplier, but to be their partner, their second source supplier. This allowed for a means for a conversation about what parts might be most critical, how their supply-chain risk is managed, and how PSE Associates might be able to collaborate to effectively implement a second source supplier for a few chosen parts.

Second source opportunities can be broken down into three categories:

- Standard/semi-standard parts.

- Engineered parts.

- Those parts that are difficult or expensive to convert to another manufacturing technology.

Standard parts offer little opportunity for us to second source because many sources already exist and the sale success mainly boils down to price. The second category is engineered parts, and it’s within this category where second source makes the most sense. These parts provide the best opportunity for us because they are designed specifically for each application and usually involve tooling or expensive qualification. Our strategy with the engineered parts is to learn from the customer what their exposure is should the sole source supplier fail to deliver. In our analysis we looked at parts that can be easily converted from one form of manufacturing technology to another. For example, can a molded plastic part be easily converted to a machined plastic part for the interim when a new supplier is tooling up and being qualified?

Conversion Difficulty

The final category is those parts that are difficult or expensive to convert to another technology. An example would be a metal injection molded part that is an amalgam of two or more separate parts in an assembly. These parts are riskier for the customer due to the substantial expense should the sole source supplier fail to deliver. The cost of qualifying and tooling a second source could easily be many times less than the cost of a supply interruption. In essence the second source is insurance of continued supply.

The other advantage we identified is that second sourcing encourages competition and innovation. Aggressive suppliers who know they have competition are eager to find ways to reduce cost without reducing margin. Sole source suppliers have little motivation to reduce cost unless they are driven by the customer.

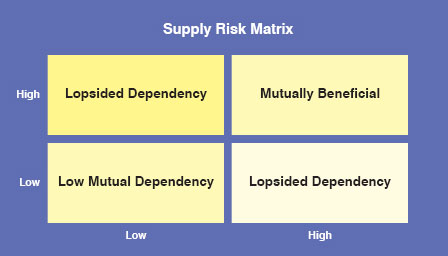

The above matrix demonstrates how a manufacturer might decide how and when to employ a second source. The relationship between the manufacturer (customer) and supplier (principal) has four distinct categories:

- Lopsided Dependency.

- Low Mutual Dependency.

- Mutual Dependency.

- Lopsided Dependency.

In an ideal world, a customer and supplier would strive for a symmetrical relationship so both the customer and the supplier are mutually benefitting from the relationship, and it is in this case when the relationship is mutual that a manufacturer would generally use a single source supplier. The other categories are asymmetrical which offsets the balance between costs incurred and service levels provided. PSE Associates can help potential customers understand the risks by performing a simple trade-off analysis like the one depicted below.

The difficulties we faced in the firearms industry are not completely unique to that particular industry. Reps continually face situations where they are up against an industry that is either facing a downturn or a boom, both of which can make new entry points difficult. A second source approach can make sense and provide a way to have a different kind of conversation. While our efforts are just now starting to bear fruit, we believe our ability to think outside the proverbial box and use our sales and engineering expertise in a new way forged a path for us to open doors that ultimately help our customers while gaining new business for our principals.

MANA welcomes your comments on this article. Write to us at [email protected].