The following article is reprinted with permission from MAFSI Matters Newsletter.

Do your reps suffer from not having a plan?

Do they fail to communicate with their partners on a proactive basis?

Are they failing to arouse their customer base?

Does their performance suffer at the time you need it most?

Hmmmmmmm! Let MAFSI (Manufacturers’ Agents Association for the Foodservice Industry) take a look and see if we can diagnose and prescribe the right approach to an appropriate treatment for this serious issue.

The obvious standout when evaluating these questions is ultimately communication and, of course, how good or bad it is. Remember, the most important part of the communication process is being able to listen first. If you can tune in to the needs of your partner, it is going to be a lot easier to keep them happy.

Setting expectations high and ending up disappointed is a regular human failing. But when it comes to business, it is actually easy to avoid this sort of disappointment by being clear about what you expect and what you are prepared to deliver. When it comes to deciding on the best way to use your rep firm to go to market, it is important to identify expectations for both the rep and the manufacturer and fully understand what it is that the manufacturers’ rep has to offer. Once you isolate all the benefits, it is easy to capitalize on the decision how to best go to market with your rep firms.

Reps generally have a well-rounded view of the manufacturer they are engaging but the manufacturer doesn’t always have a solid understanding of what it is exactly that the rep firm is going to do, and this is where the communication process really needs to be front and center in order to keep the relationship running smoothly. Bringing the expectations of both parties into the forefront of the negotiation and discussion lays the ground work for a long-term agreement where both parties know exactly where they are going, making it easier to build strategies for success.

It Is Important That Reps Feel Appreciated

Reps are not just a step in the sales channel — they are part of the channel. It is just as important for reps to see themselves in this way as it is for manufacturers to appreciate the rep function. The old parental advice ‘if you don’t respect yourself, you can’t expect anyone else to respect you’ is probably appropriate to keep top of the list. With that said, it should be stated that reps are coin operated and know where their bread is buttered. They don’t need to have their egos stroked; they just need to know that they are valued, particularly for the long term. This acts as the incentive to keep delivering the goods. The old quote ‘you’re my favorite rep, as I can always count on you to give that extra discount for the sale’ is not really something a rep wants to hear, nor is it something that makes a rep want to work hard for their partner.

Most, if not all reps and manufacturers have their favorite partner or two. But what is it that makes these partnerships such a standout. The answer to this question can be found in the do’s and don’ts of rep-manufacturer relationships. A partner who has mastered these rules is already ahead of the pack.

The Must Do’s for a better relationship:

- Be exclusive (manufacturers — no house accounts, and reps — always notify your manufacturers of a line change).

- Set boundaries (call backs, meeting schedules, etc.).

- Be a good communicator (copy each other on correspondence and never make unilateral deals behind either’s back).

- Be prompt (pay your representatives on time and accurately [it’s their only income!] and reps do what you say you are going to do when you say you are going to do it).

- Plan one-on-one time (work with each other on realistic market potential, sales forecasts and quotas).

- Trust each other (reps and manufacturers ultimately have each other’s best interests at heart — continually work to augment each other’s stature in the market).

Once a manufacturer makes a decision to hire a rep firm, the risk and burden of deliverance transfers immediately to the rep. While a bad choice in a rep can bring time delays and forfeiture of deadlines to a manufacturer, the ability to hire another firm leaves the manufacturer with the final power play. Delivering the goods, so to speak, is what the rep firm focuses on because if they don’t they lose. This is the greatest win-win for the manufacturer. When a rep firm enters into an agreement with a manufacturer it is because they plan on making good on their service and promise because if they don’t, the price and stakes are high. The confidence that can be found in the rep function is undeniable. It is not all about the promise of delivery, though. Let’s look at exactly what goes in to the rep function behind the scenes.

What Can Rep Agencies Afford, and Where Do They Invest Their One Major Resource, TIME?

When it comes to the expenses of a rep firm, size does matter. In a recent survey of MAFSI members, the following data were gathered.

- Average size of the rep sales force:

- 40% — 3 or less

- 70% — 5 or less

- 90% — 8 or less

- Average total expense per salesperson $85 to $120k

Average inside sales support for a rep:

- 1 sales coordinator for every 2.5 outside salespersons

- 1 admin staff per 500k of revenue

Typical rep organization:

- 9 employees

- Family business

- Main sales office with admin support

- 2 remote salespeople

Average commission by line:

- 31% = 5% commission

- 35% = 6% commission

- 18% = 7% commission

Average agency sales/revenue:

- 65% — $15 million annual sales or less

- 90% of all reps — under $30 million

- Average agency revenue under $1.5 million

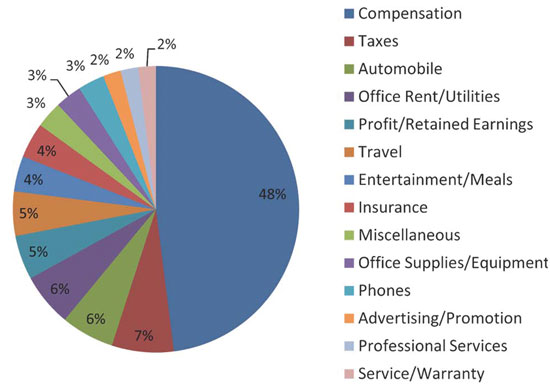

So Where Do the Commissions Go?

Here is an average breakdown on the commission expenditure:

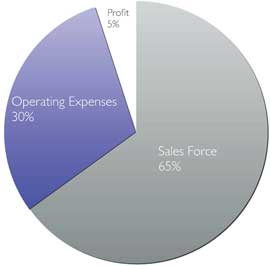

The graph to the right reflects the average rep sales force operating expense and profit.

The graph to the right reflects the average rep sales force operating expense and profit.

- Operating expenses 30%

- Profit 5%

- Sales Force 65%

What does it take to make a 5% return on a line card? How many lines do reps actually carry on average?

- 20% represent 10 lines or less

- 40% represent of 17 lines

There is a fine line between how many lines a firm should carry and running a controlled expense department. The following results were reported as being the mainstay areas for expense reduction and cost cutting:

- Cut travel

- Cut expenses and overhead

- Cut healthcare

- Cut salaries

- Add more lines — proceed with caution

Areas where rep firms are looking to expand their annual expenses are these:

- Investing significantly in technology as a means to track expenses and grow service

- Hiring new staff

- Installing or expanding the use of in-house test kitchens

- Show rooms are a great resource and many firms are growing their show floor

- 50% of respondents to 2012 MAFSI survey have kitchen/showroom facilities (approx $75,000 investment)

On the issue of reps also being distributors, MAFSI learned that 44% redistribute some products and the main source of redistributed product lines were microwaves, filters, ranges and ice machines. 100% of the sales were to dealers.

Coordinating installations is not something that MAFSI reps are known to focus on. In the recent survey only 19% reported being involved in installation while the remaining 81% had no involvement in this install process.

Conclusion

Manufacturer-agent dysfunction can be a serious condition and you should consider having a discussion about it within your partners. In a world where the landscape is constantly changing and technology continues to provide benefits as well as challenges, survival of the fittest is the name of the game. Both reps and manufacturers continue to be challenged by the process of taking a product to market, but change is never ending. You must ask yourself the tough question of how you want to deal with it.

The reps of the future need to be equipped to handle myriad tasks and being average won’t necessarily cut it. A rep that can enter his own order on the go, knows his way around technology, knows how to respond to line overlap, drives a team environment, values himself as a rep, believes wholeheartedly in the rep function and knows the importance of communication, is going to stand at the front of the pack. Firms need to be vigilant in their search for excellence, knowing that having the great staff is not just a given, you have to work at it and make it a priority.

Manufacturers — keep the lines of communication open. Those words are simple but they carry a world of meaning. For instance, if something goes wrong, make sure the rep is first to know. Be sure that you communicate with the customer only through the rep. Explain any company personnel changes, product alterations or other changes promptly and accurately to your reps. Acknowledge reports you receive from the field and answer reps’ questions promptly.

These simple changes will result in the achievement of the following, which is sure to cure dysfunction between manufacturers and agents:

- Increased income

- Market knowledge influence and feedback

- Market share growth

- Achievement of sales goals

- Sales force continuity

- Clear strategic direction

- Increased customer base

MAFSI exists to improve, promote and support the rep function and to ultimately cure, once and for all, any disruption in the manufacturer-agent relationship.